Engine valve head & seat grinder machine is special purpose machine for engine valve. It is suitable for grinding head OD, chamfer and rough grinding seat face. We have two types: Single station and double station grinding machine. Double station engine valve seat grinding machine for sale can process two pcs engine valve at the same time, increase the efficiency. suitable for mass production and connection production.

|

Stem diameter :

|

|

|

Overall length :

|

|

|

Head diameter:

|

|

MUG-B

Engine Valve Head & Seat Grinder Machine is special purpose machine for engine valve. It is used for grinding OD, rough grinding seat face of engine valve.

Ranging from stem diameter:5 mm to 8 mm, Head diameter: 20 mm to 50 mm, Overall length: 80 mm to 150 mm. The machine can be single production and also can be connection production. Our equipment are continually ungrade with latest technologies in processing engine valve.

We have two types this machines. one type is single station valve grinding machine, another types is double station seat engine grinder for valve machine. It can process 2 PCS engine valve at the same time. Increase the quantity and efficiency. Suitable for mass production.

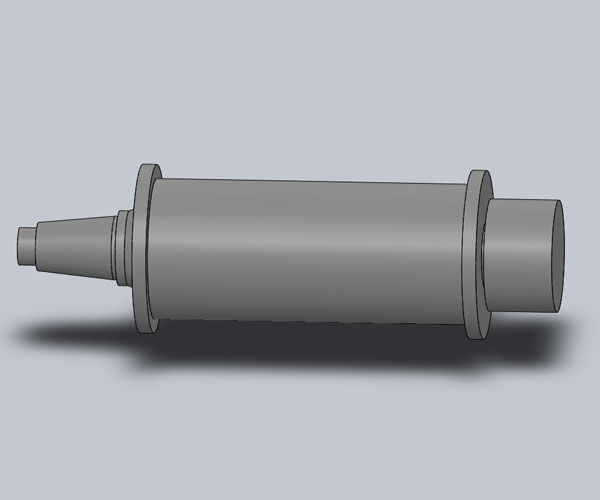

Mechanical Spindle 6000 rpm high-speed spindle. Adapts Germany FAG precision bearing. High accuracy and easy to maintenance and changeover One year warranty |

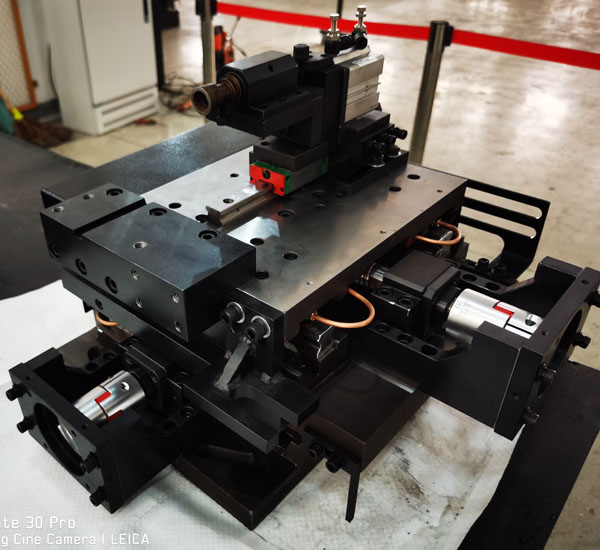

Control system Adapts Mitsubishi PLC Control system, Mitsubishi motion system & Mitsubishi touch screen All parameters can be set and display on touch screen Can store more sets program, you can choose according to different process technology |

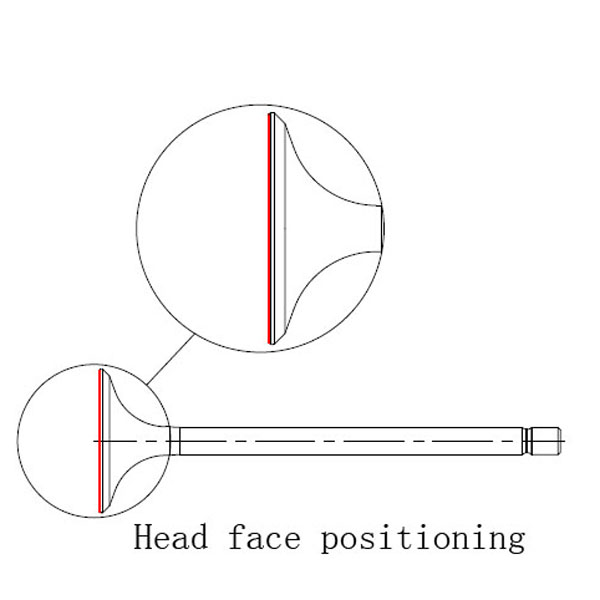

Feeding way & Positioning way Precision sliding table composed of linear guide. Moving according to air cylinder; Head face of engine valve positioning ,roller clamping assist. |

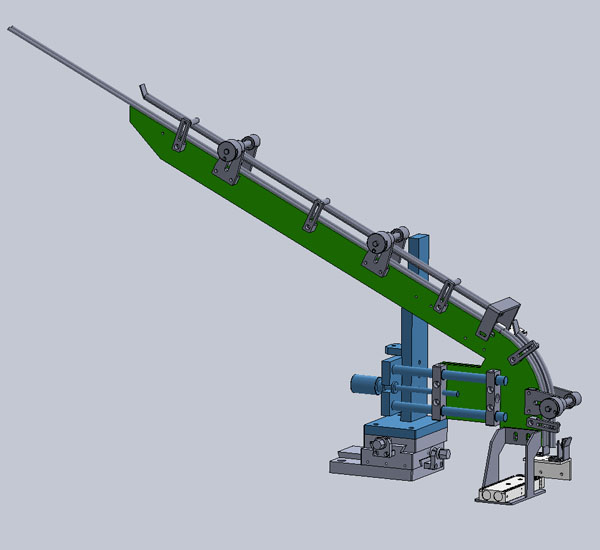

Loading & unloading systemLoading & unloading system The rails can meet different size valves and easy to adjust The rest actions should carry out with grinding except for loading & unloading system Loading & unloading system has proper protection measures and don't affect the operator to change the fixture, wheel and other toolings If the loading & unloading system is out of order, the machine will ring and stop the cycle. |

Feed Slide With X-axis and Y-axis, easy to operate through the touch screen. |

| Before Processing | ||

| Processing range | Head diameter: 20-50 mm, Stem diameter: 5-8 mm, Length: 80-150 mm | |

| Material | 21-4N, 4Cr10Si2Mo, Imported SUH:3, SUH:35, etc. Hardness: 35-45 HRC | |

| Stem run out: 0.01 mm, Head run out : 0.1 mm | ||

| Seat Angle | 45-60 degree | |

| Grinding allowance | Within 4 mm | |

| After Processing | ||

| Processing accuracy | Head run out | Max ±0.03 mm |

| Seat run out | Within ± 0.05 mm | |

| Roughness | Within Ra1.6 | |

| Cycle time | Within 7s/piece ( according to valve size ) | |

| Wheel size | CBN Wheel | 380*160*20 mm |

| Wheel speed | m/s | 80-120 |

| Air pressure | 0.4-0.6 Mpa | |

| Water discharge | 20L/Min | |

| Power | 8 KW | |

| Current | 380V/50Hz | |

| Machine size | 2100*1950*2350 mm | |

| Machine Weight | 2000 kg | |

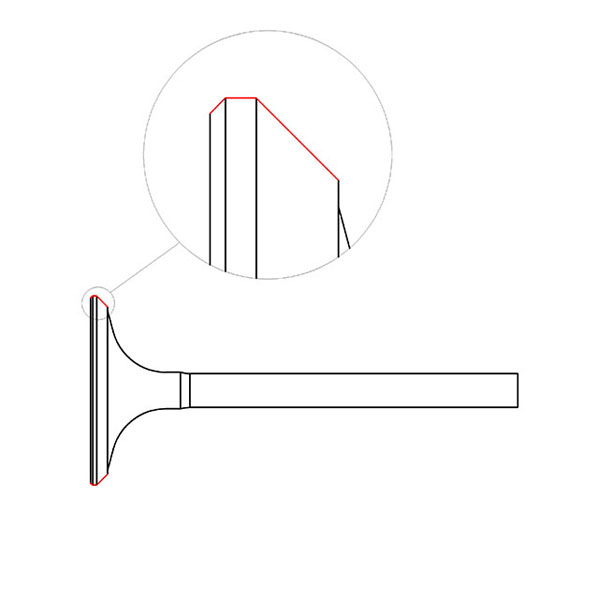

Rough grinding seat face, head diameter & head chamfer Engine valve head & seat grinding machine can grind rough seat face, head diameter and head chamfer at the same time. We use profiled CBN wheel to process. more accuracy. CBN wheel adapts electroplate treatment. Can reuse after re-electroplate Both sides can be used |