Double Statation electrical upsetting machine products is used for forging the round bar. As one of the most professional electrical upsetting machine products manufacturers in China, Tianzhijiao provides electrical upsetting machine products featured servo control, more accuracy and easy to operate.

|

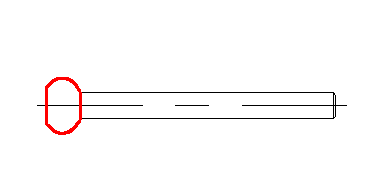

Stem diameter :

|

|

|

Overall length :

|

|

Electrical upsetting machine products deforms the material by applying electric current through conduction or induction, followed by stamping to obtain the desired shape. The workpiece is held against an anvil and clamped between two-part jaws. A high-density electric current at very low voltage flows between the jaws and the anvil plate and heats the exposed portion. The desired shape is upset via the axially applied pressure.

It consists of servo system, deceleration system, guide block mechanism, anvil electrode, anvil seat and alloy conductive block.

The servo system drive the guide block. In the process to make sure forging force balance.

Anvil electrode adapt T2 electrolytic copper. Installed on guide block. Another side connection with transformer.

Anvil seat and guide block connect with anvil electrode.

It consists of clamping cylinder, guide mechanism, clamping electrode and jaws conductive block.

Add auxiliary support to prevent from bend.

Adapt low pressure circuit. Supply the oil by the motor driven the vine pump. The hydraulic valve is mounted on the integrated circuit block. Adapt proportional regulator.

Heating system

30 KVA single phase transformer. The heating current is controlled by dedicated Thyristor controller. Stepless regulator and constant current heating.

Conrol system

Mitsubishi system, Mitsubishi touch screen and Mitsubishi servo control system

| # | Name | Parameter |

| 1 | Max. working force | 6.3 Mpa |

| 2 | Max. forging force | 20KN |

| 3 | Max. Stroke of forging cylinder | 300 mm |

| 4 | Max. Stroke of anvil cylinder | 150 mm |

| 5 | Max. Stroke of clamping cylinder | 40 mm |

| 6 | Rod diameter | 5-8 mm |

| 7 | Max. length | 300 mm |

| 8 | Transformer power | 30 KVA |

| 9 | Frequency | 50 HZ |

Engine valve

Fastener Round metal Bolts |

By continuing to use the site you agree to our privacy policy Terms and Conditions.