We design and produce each machine according to customer demands and requests. Professional technology, reasonable price, accurate delivery time and good after-sales service are our advantages!

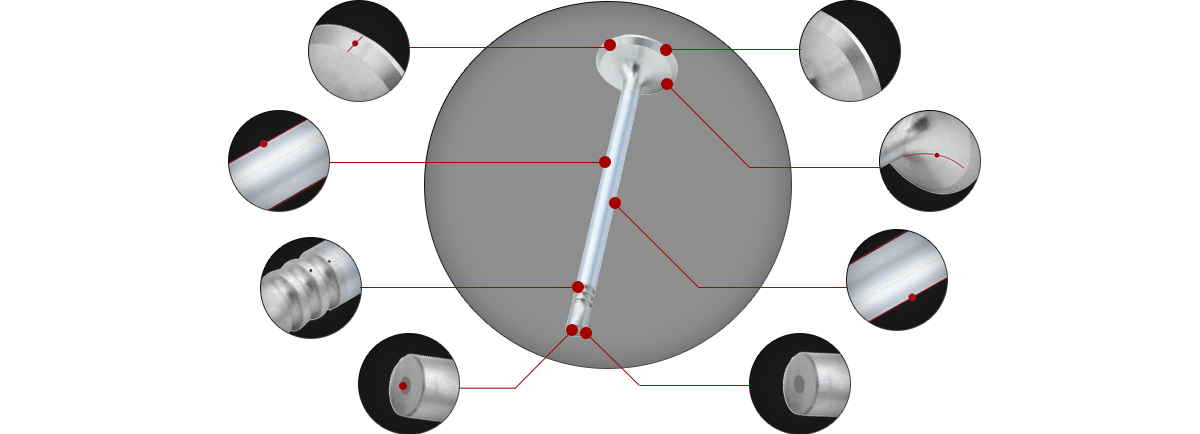

Automatic Engine Valve Production Line

Fully Automatic Engine Valve Production Line

New Design Automated Engine Valve Production Line

Automatic Production Line for Engine Valve

Our company established in 2008 year. Having senior technical staff 10 person that they have many years experience in valve equipment field. Technical service staff 20 people. All the equipment adapt PLC and Servo Control way. With automatic machine hand to upper and lower. Not only automatic production, but also connect production.

Learn More TianzhijiaoThe valve cone surface (also known as the valve seal cone surface) is the critical mating surface for the valve seat ring. Its roundness and roughness are two vital indicators of geometric accuracy and surface quality, directly impacting engine performance, efficiency, reliability, and durability.

Learn MoreAs grinding equipment specifically designed for high-precision cylindrical components like engine valve stems, the performance of CNC centerless grinding machines directly determines valve stem machining quality and production efficiency. Systematic daily maintenance is crucial to ensure this precision equipment remains in optimal condition. A comprehensive maintenance system not only extends equipment lifespan but also guarantees stable machining accuracy, preventing production losses from unexpected downtime.

Learn MoreBy continuing to use the site you agree to our privacy policy Terms and Conditions.