© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

Forging is one of the oldest and most important metalworking processes in human history, dating back thousands of years to when blacksmiths shaped hot metal using hammers and anvils. Today, this ancient craft has evolved into a highly precise industrial process, supported by advanced forging machines capable of producing components with superior strength, durability, and structural integrity. But what exactly are forging machines, how do they work, and what types are used in modern manufacturing? Let’s explore these questions in depth.

A forging machine is an industrial device used to shape metal by applying compressive forces. Instead of removing material (as in machining) or melting it (as in casting), forging machines reshape solid metal into the desired form by deformation, typically under high temperature or pressure. This process improves the mechanical properties of the material, such as its tensile strength, grain structure, and fatigue resistance.

In essence, forging machines reproduce what blacksmiths once did manually—but on a larger scale, with greater accuracy, repeatability, and production speed. They are integral to producing critical components in industries such as automotive, aerospace, defense, oil and gas, and heavy machinery manufacturing.

All forging machines operate on the same fundamental principle: controlled deformation. A metal workpiece, often preheated to increase its plasticity, is placed between two dies that contain the shape of the desired part. When the machine applies compressive force, the metal flows and fills the cavity between the dies, taking on its final form.

There are two major categories of forging based on temperature:

Hot forging – conducted at high temperatures to make the metal more ductile and reduce the risk of cracking.

Cold forging – performed at or near room temperature, offering better dimensional accuracy and surface finish.

The choice depends on the type of material and the specific mechanical requirements of the part being produced.

Forging machines come in a wide variety of types, each suited for specific applications and production scales. The most common categories include:

1. Mechanical Press Forging Machines

Mechanical presses use a crank or eccentric mechanism to deliver controlled and repeatable blows to the workpiece. These machines are favored for high-volume production and can achieve precise tolerances. They operate with a fixed stroke length, making them ideal for parts that require consistent deformation, such as gears, bolts, and connecting rods.

2. Hydraulic Press Forging Machines

Hydraulic presses use hydraulic fluid pressure to apply force gradually and uniformly. Unlike mechanical presses, they can maintain pressure for longer durations, allowing better control over the forging process. Hydraulic presses are suitable for producing large or complex parts that require deep penetration of the metal, such as turbine discs, shafts, and rings.

3. Screw Press Forging Machines

Screw presses generate force through the rotation of a large screw that drives the ram downward. The energy is transmitted through the screw mechanism, resulting in a powerful yet controllable impact. These machines are particularly useful for precision forging, where both impact and dwell time must be finely tuned.

4. Drop Hammer Forging Machines

Drop hammers deliver repeated high-energy blows to shape the metal. The ram is raised and then dropped onto the workpiece, which sits in the die. There are several variants, such as board drop hammers and air-lift hammers. Drop forging is widely used for producing parts that require high strength and grain flow alignment, such as crankshafts and aircraft components.

5. Upset Forging Machines

Upset forging involves compressing the length of a heated bar to increase its diameter. Specialized upset forging machines are designed for this process, producing fasteners, bolts, and automotive components efficiently.

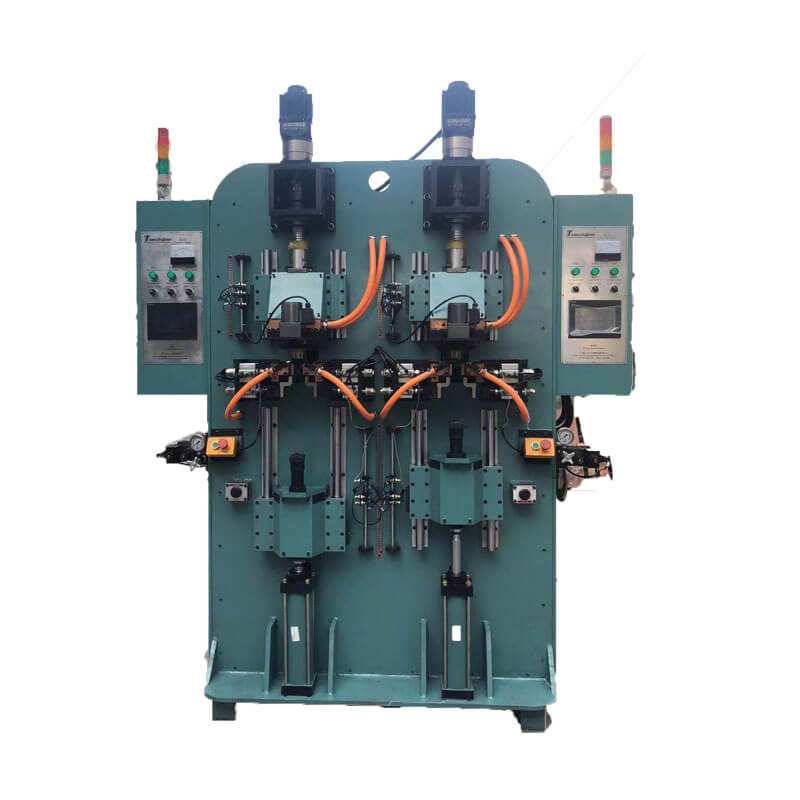

Despite variations in design, most forging machines share several core components:

Frame: The main structure that supports all mechanical parts and withstands the stress during operation.

Ram or Slide: The moving part that transmits force to the workpiece.

Dies: Specially shaped tools that define the final form of the forged part.

Drive Mechanism: Converts energy (hydraulic, pneumatic, or mechanical) into movement.

Control System: Modern forging machines include computerized systems for precision control, monitoring, and safety.

These elements work together to ensure the metal deformation process is consistent, safe, and efficient.

Forging machines offer several advantages over other metal forming or shaping methods:

Improved Mechanical Properties: Forging refines the metal’s grain structure, enhancing strength and toughness.

High Production Efficiency: Automated machines enable mass production with minimal waste.

Dimensional Accuracy: Modern CNC-controlled forging machines achieve precise tolerances and repeatability.

Material Utilization: Forging uses nearly the entire workpiece, minimizing material loss compared to machining.

Consistency and Quality: Automated control systems ensure uniformity across large production batches.

These advantages make forging machines indispensable for manufacturing safety-critical components, especially in the automotive and aerospace industries.

Forging machines are used to produce a wide range of metal components, including:

Automotive Parts: Crankshafts, connecting rods, gears, and axles.

Aerospace Components: Turbine blades, landing gear, and structural supports.

Industrial Equipment: Hydraulic cylinders, shafts, and couplings.

Tools and Hardware: Wrenches, hammers, and fasteners.

Their ability to create parts with excellent fatigue resistance and reliability makes them a preferred choice for high-performance engineering applications.

The forging industry continues to evolve with advancements in automation, control systems, and digital integration. Some key trends include:

CNC and Servo-Controlled Systems: Offering precise control over stroke, speed, and pressure for consistent quality.

Energy Efficiency: New hydraulic and electric-drive systems are designed to reduce energy consumption.

Smart Forging: Integration of sensors and IoT technology allows real-time monitoring of temperature, pressure, and die wear.

Simulation Software: Virtual forging simulations help engineers optimize process parameters before production, minimizing trial and error.

These innovations have not only improved efficiency but also reduced costs and environmental impact.

Forging machines operate under extreme pressure and temperature conditions, so proper maintenance and safety are critical. Regular inspection of hydraulic systems, die alignment, lubrication, and cooling systems ensures smooth and safe operation. Workers must follow strict safety protocols, including protective gear, machine guarding, and emergency stop mechanisms, to prevent accidents.

Manufacturers often adopt predictive maintenance systems that use sensors and data analysis to detect wear or faults before failure occurs, reducing downtime and improving productivity.

Forging machines represent the perfect blend of tradition and technology. What began as a manual blacksmithing process has transformed into a sophisticated, automated production system that plays a vital role in modern manufacturing. By reshaping metals under immense force, forging machines create components that are not only strong and reliable but also efficient to produce.

Whether in automotive engines, jet turbines, or heavy machinery, the precision and power of forging machines continue to drive progress across industries worldwide. Their evolution underscores the importance of innovation in metal forming—a field where strength truly meets precision.

By continuing to use the site you agree to our privacy policy Terms and Conditions.