© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

With the rapid development of industry, the types and numbers of machine tools have increased rapidly, and the technical requirements have also greatly increased. The invention and use of the quenching machine not only improved work efficiency, but also reduced unnecessary costs for the company. Quenching machines may not be common for everyone. The quenching machine is a machine tool that uses an induction heating power source for quenching. There are two main types of quenching machines, which can be divided into numerically controlled quenching machines and high-frequency quenching machines.

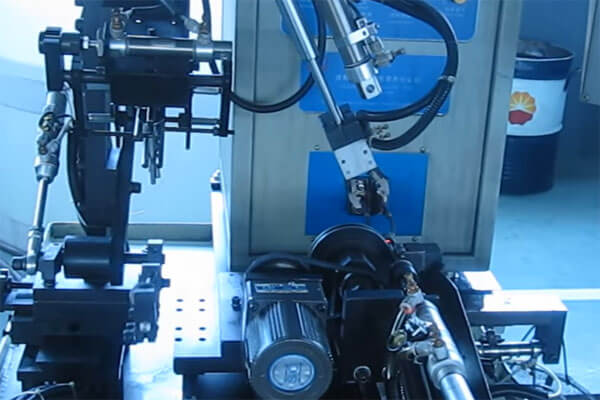

So what is the difference between CNC quenching machine and induction quenching machine? I believe this is a place that confuses everyone. Let's take a look at the details of professionals. The CNC quenching machine is composed of a bed, a double-layer precision worktable, an upper center seat adjustment sliding mechanism, an upper center assembly, a table movement and transmission system, a spindle rotation and transmission system, a part rotation and an upper center adjustment mechanism, and a balanced balance. Cover frame, electrical numerical control parts and so on. So what is a horizontal CNC quenching machine? In fact, CNC quenching machine is divided into two types: vertical CNC quenching machine and horizontal CNC quenching machine. Horizontal CNC quenching machine is the design of the equipment.

First, let's take a look at the characteristics of CNC quenching machines: CNC quenching machine adopts PC industrial digital control system, with advanced performance, convenient debugging and debugging, which can meet the quenching requirements of complex work pieces to the greatest extent. Quenching methods can be realized: continuous scanning quenching, synchronous quenching, segmented continuous scanning quenching (division) setting. No need to switch, the same below), split and quench. Applicable typical work piece (within the corresponding size range) shafts: various shafts, stepped shafts, gear shafts, cam shafts, half shafts, outer circumferences, end faces of disc-shaped parts, etc. However, induction hard machine tools are leaders in the construction industry. Quenching is widely used in steel heat treatment process. High frequency quenching is mostly used for industrial metal surface quenching. It is a metal heat treatment method that causes the work piece surface to generate a certain induced current, rapidly heats the surface of the part, and then rapidly quenches.

The high-frequency quenching process of high-frequency quenching equipment refers to a heat treatment method in which the surface of a work piece is locally heated and cooled by using a high-frequency current (30K-1000KHZ) to obtain a surface hardened layer. This method only strengthens the surface of the work piece to a certain depth, and the core basically maintains the structure and properties before processing, so that a combination of high strength, high wear resistance and high toughness can be obtained. Due to local heating, it can significantly reduce quench deformation and energy consumption. Because of the above characteristics, high frequency quenching is widely used in the processing industry.

Tianzhijiao Precision Machinery has been designing and manufacturing CNC Valve Grinding Machine more than ten years. We are a professional China CNC quenching machine manufacturer. We have small, highly skilled team that offer a personal service worldwide. Many our customer use our machine all the time and have good reputation.

By continuing to use the site you agree to our privacy policy Terms and Conditions.