© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

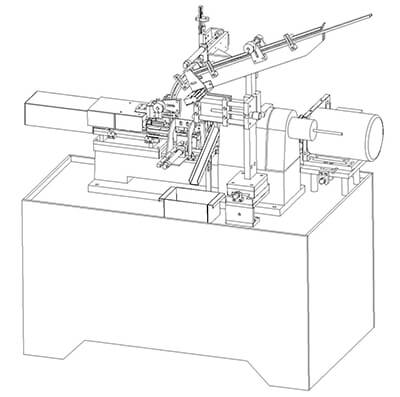

When considering what a valve tip drilling machine price maybe, one of the first things you should consider is having an understanding of how the machine works. So, join us as we explore the powerful makeup of the CNC value tip drilling machine.

What Is Grinding In CNC Machines?

Grinding machines employ an abrasive machining technique that delivers a surface finishing and tolerance which cannot be achieved through any other process.

And outstanding quality about the grinding machine is the fact that they are capable of giving a high dimensional accuracy, which is usually not obtainable using any other machining process. Also, the engine valve grinding machine manufacturer also design the grinding machine to deliver a tolerance level below ±0.0002 inch.

When operated under the right condition, grinding machines can deliver an accuracy level that is as tight as 0±0.00003 inch in a consistent and reliable manner.

Due to the high precision level of grinding machines, they have seamlessly become an integral part of various industrial applications. Some industries utilizing the grinding machine include aerospace, machine tools/molds, medical, automotive, and even tooling and products where grinding machines are used on a daily basis.

Types of Grinding Machine

A visit to the grinding machine market will leave you with an endless list of different types in the market.

However, it is very important to team up with a reliable and competent engine valve grinding machine manufacturer for all your CNC valve tip drilling machine needs.

Some typical example of grinding machines available include;

1. Cylindrical

2. Thread

3. Gear

4. Cam and crankshaft grinders

5. Surface grinders

6. Tool and cutter grinders etc.

Similarly, grinding machines can also be grouped based on the type of grinding application they perform. Some of such categories of grinding machine based on the type of grinding include;

1. Surface

2. Form

3. Inner diameter (ID)

4. Outer diameter (OD)

5. Plunge

6. Thread

7. Through-feed grinding

8. Centerless

Outstanding Features of Grinding Machines

1. High Productivity and Precision

Due to the high productivity as well as the high level of capability and precision for unattended operations of the full CNC machines, they have recently grown to outshine the manually operated toolroom grinders, which are no more in vogue.

2. Excellent Surface Finish

Besides the high level of precision of the grinding machines, they also have a high-quality surface finish, which remains the primary reason why a lot of people now flock the grinding machines.

Typically, a grinding machine can produce a surface finish of about 16microinch Ra and below, and this is about half of what is produced using a milling machine. In extreme cases, the grinding machines can be used to achieve a super finish of about 8 microinches and even 2 microinches which are regarded as being a micro finish.

Bottom Line

Grinding machines such as the CNC valve tip drilling machines are powerful machining tool that has found relevance in various industrial applications and sector.

Due to their high level of precision, speed, and surface finish, grinding machines have come to outshine the traditional milling machine that was in use before now.

To get the best value for a CNC valve tip drilling machine, the services of a reliable and professional engine valve grinding machine manufacturer should be your goal.

By continuing to use the site you agree to our privacy policy Terms and Conditions.