© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

About Engine Valve

Suzhou Tianzhijiao Precision Machinery Co.,Ltd has more than ten years experience in processing engine valve. We manufacture engine valve processing equipment. if you have demands. don't hesitate to contact us.

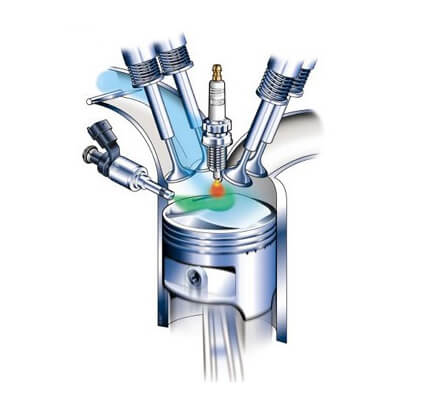

Valve is important components of engine. The role of the valve is dedicated to the import of air into the engine and exhaust emissions from combustion.

Valve Structure

From the engine structure, divided into the intake valve (inlet valve) and exhaust valve (exhaust valve). The role of the intake valve is the air sucked into the engine, mixed with the combustion of fuel; exhaust valve is the role of exhaust emissions after burning and cooling.

Valve Material

Valve material in mainland China is usually divided into 40Cr, 4Cr9Si2, 4Cr10Si2Mo, 21-4N and 23-8N of 5 species. 5Cr8Si2, 4Cr9Si3, 21-2N, 21-12N, 23-8N, XB, etc. have been in a number of imported models in large quantities. High-temperature nickel-based alloy in high-load engine exhaust valve also began to use.

Valve Types

From the valve structure of the finished product classification, usually divided into the entire root valve, bimetal butt welding valve and hollow filling sodium valve.

Valve Technology

Additional process is usually the top of the welding piece, the top surfacing, cone surfacing, surface nitriding, chrome-plated surface treatment.

Valve Functions

Its role is specifically responsible for the import of fuel to the engine and exhaust emissions, the traditional engine each cylinder has only one intake valve and an exhaust valve, this design structure is relatively simple, low cost, easy maintenance, low speed performance is better, shortcomings Is difficult to improve power, especially when the high-speed inflatable low efficiency, performance is weak.In order to improve the efficiency of intake and exhaust, multi-valve technology is now more common is the layout of each cylinder has four valves (there are three or five single-cylinder valve design, the same principle, such as the Audi A6 engine), 4 cylinder Is the 16-valve, we often see in the car data "16V" on the engine that a total of 16 valves. This multi-valve structure is easy to form a compact combustion chamber, the injector is arranged in the center, so that oil and gas mixture can burn more quickly and more uniform, the valve weight and opening of the appropriate reduced, the valve open or closed faster.

By continuing to use the site you agree to our privacy policy Terms and Conditions.