© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

Valve grinding machine is a highly efficient automatic machine tool. It has a wide range of processing properties and can process arcs, straight cylinders, slanted cylinders and various threads. It has various compensation functions such as linear interpolation and circular interpolation and has played a good economic effect in the mass production of complex parts.

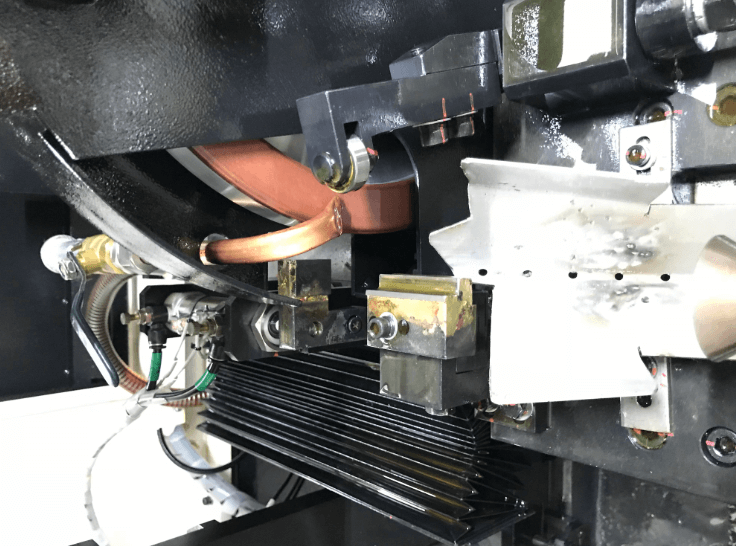

Because the axis of the guide wheel and the axis of the grinding wheel have an inclination angle α, the workpiece and the guide wheel are not in line contact. In order to keep the workpiece in line contact with the guide wheel, the shape of the guide wheel should not be cylindrical, but should be made into a hyperboloid. The hydraulic cylinder is used to drive the external grinding with two axes and the two cylinders are used to control the feed of the wheel frame and the table. The electric valve grinding machine is manually controlled by the change of the dial. In the process measurement, the measuring instrument is also used to control. And our company's CNC grinders, valve grinders use CNC systems to achieve control, using servo drives to replace the cylinder drive of ordinary grinders. Through the servo system to achieve linkage control and cooperate with the online measuring instrument, the linear encoder can achieve the overall closed-loop control.

Valve grinding machines for sale have annular parts of radial bearings with one or more raceways. Because the positioning of the workpiece during the grinding process is determined by the grinding wheel, the guide wheel and the supporting plate, the center position of the bearing ring is not fixed in the radial plane with the movement of the workpiece. Because the inner and outer shells are positioned in an irregular wavy shape, with the rotation of the ferrule, the center of the ferrule moves periodically in the radial plane, so there is no fixed position.

The valve grinding machine surface of the bearing ring is the basis for positioning, which affects the shape and size of the part being ground, which is reflected as machining errors. In addition, the movement of the ferrule is controlled by the grinding wheel, the guide wheel and the support plate, and the control of the guide wheel is the main factor. The stability of the ferrule movement depends not only on the machine's motion transmission chain, but also the actual situation of wheels and pallets, such as shape, weight, material of guide wheels and pallets, surface condition and so on.

Purchasing products from the same manufacturer of the same system can be better and paying attention to the identity of the control system is important. The selection of machine tools is to ensure that the functions and accuracy of the equipment are not idle or wasted. Do not choose functions that are not related to your own needs, and do not choose machine tools that you need but do not have this function.

By continuing to use the site you agree to our privacy policy Terms and Conditions.