© 2019 Suzhou Tianzhijiao Precision Machinery Co.,Ltd. All rights reserved. Site Map Designed by iwonder.cn

Friction welding, commonly known as spin welding, is a controlled machining process for joining SIMILAR or DISSIMILAR (Bi-Metal) combinations of materials. The ultimate goal of spin welding is to have a 100% weld throughout the full joint interface. This means, given suitable materials, the weld union or interface strength is equal in strength to that of the parent metals. This process yields a high-strength, low-stress, small heat-affected zone (HAZ) weld with no porosity, and in most cases, eliminates the need for costly pre-machining or costly tooling. You may have heard of this friction welding process or welding interface referred to as spinning, welding, fusing, bonding, marring, or union. Friction welding is a well-established process developed in the 1890s and is widely accepted throughout many different industries and global markets.

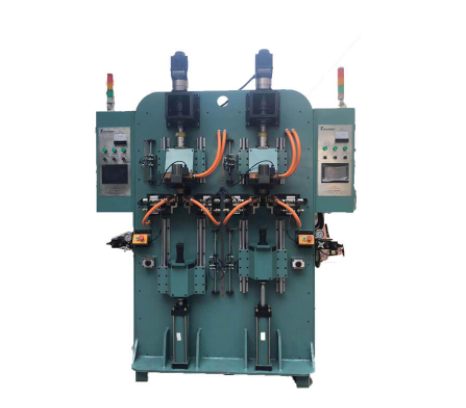

How Friction Welding Works

Friction welding works by following the fundamentals of friction. The process uses friction to create a plastic-forming heat at the weld interface. For example, the friction heat created on steel is usually around 900–1300 degree centigrade. After the appropriate temperature is achieved, an external pressure force is increasingly applied until the workpieces form a permanent weld joint.

While there are several different friction welding types, they all follow a common working principle. First, one workpiece is placed in a rotor-driven chuck, while the other is held stationary. The rotor allows the mounted workpiece to rotate at high speeds. A pressure force is applied to the stationary workpiece, bringing it into contact with the rotating workpiece. When the workpieces touch, a high friction force is created and generates significant heat on the surfaces in contact until the two materials soften, also referred to as plasticizing. Once the materials reach a plasticized state, a higher forging pressure is applied to the static piece, forcing the two materials to meld together. After the parts meld together and the interface begins to cool, the rotor stops once the temperature reduces and the materials re-solidify.. The forging pressure is maintained for a few seconds and then released, at which time the weld is completed.

Applications

Friction welding can be used to build better industrial rollers, tubes, and shafts. The process is often used to manufacture these subassemblies for industrial printers, material handling equipment, as well as automotive, aerospace, marine, and oil applications. Other examples of components include gears, axle tubes, drivelines, valves, hydraulic piston rods, truck roller bushes, pump shafts, drill bits, connection rods, etc.

Benefits

Friction welding is an eco-friendly process that doesn’t create smoke or release other harmful toxins into the atmosphere. Next, it offers a lot of control over the heat-affected zone, which reduces change to material properties. It also doesn’t require filler metal (which saves cost on raw material). Last, friction welding offers simple automation, fast speeds, efficient welds, and the ability to combine a variety of metals.

Ready to Start Friction Welding?

If friction welding sounds like it could benefit your application, please contact us. During our conversation we can discuss which type of friction welding might be your best option and if we are the best-fit provider to inertia weld your subassemblies.

By continuing to use the site you agree to our privacy policy Terms and Conditions.